Amongst the naysayers of climate change there is a strong argument that regulation protecting environment retards development. Claims that regulations either advance or retard innovation and development are overly simplistic. Value of development cannot be a simple intrinsic price but embodies many extrinsic parameters too. Regulations do not necessarily always throttle the speed of development but in fact compels us to innovate. It propels better performance and longetivity of products and systems. A recent study discusses the story of five ideas that were spurred by regulations. Everyday products that have made our lives far more sustainable than a few decades ago such as the incandescent light bulb or energy efficient appliances are examples of direct results of stricter regulations being applied for use of said product in itself. But there are many regulations that were applied to one set of industry and the benefits of the regulations have been reaped by another industry. This is true more so for the construction industry and infrastructure systems.

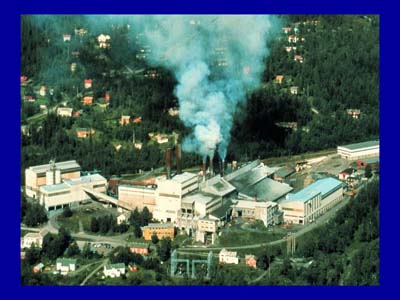

Prior to the regulations laid down on coal industry, ash particulates formed from burning coal were dispersed into the environment causing large amount of air pollution. Similarly, silica fume a by product of reducing high-purity quartz with coal or coke and wood chips in an electric arc furnace during the production of silicon metal or ferrosilicon alloys, was also discharged into the environment before stricter laws were put in to place in 1970s . Environmental regulations forced the power industry to develop high performance bag filters to collect fly ash or silica fume rather than discharging it into air. The next question was utilization of these collected by-products. Similarity of chemical composition of fly ash or silica fume with cement has lead to its extensive use in the construction industry. Usage of fly ash, silica fume or slag (from steel industry) in cement as partial replacement enhances the strength, quality and long-term performance of the structure. It’s a win-win situation for both the stakeholders as well as the producers. Currently, 5 billion tonnes of concrete is produced worldwide of which nearly 40 % is made using industrial by-products as partial cement replacement additives.

Prior to the regulations laid down on coal industry, ash particulates formed from burning coal were dispersed into the environment causing large amount of air pollution. Similarly, silica fume a by product of reducing high-purity quartz with coal or coke and wood chips in an electric arc furnace during the production of silicon metal or ferrosilicon alloys, was also discharged into the environment before stricter laws were put in to place in 1970s . Environmental regulations forced the power industry to develop high performance bag filters to collect fly ash or silica fume rather than discharging it into air. The next question was utilization of these collected by-products. Similarity of chemical composition of fly ash or silica fume with cement has lead to its extensive use in the construction industry. Usage of fly ash, silica fume or slag (from steel industry) in cement as partial replacement enhances the strength, quality and long-term performance of the structure. It’s a win-win situation for both the stakeholders as well as the producers. Currently, 5 billion tonnes of concrete is produced worldwide of which nearly 40 % is made using industrial by-products as partial cement replacement additives. The production of Portland cement is an extremely resource and energy intensive process where every tonne of cement requires about 1.5 tonnes of raw materials. In addition, each tonne of cement produced releases approximately one tonne of carbon dioxide (CO2) into the environment. Thus the production of Portland cement is a significant contributor to atmospheric pollution and the green house effect. Addition of fly ash or silicafume as partial replacement to Portland cement helps in reducing usage of extensive raw materials as well CO2 emissions. Each tonne of cement replaced by fly ash reduces the CO2 emissions by approximately one tonne. Thus, regularizing two industries, which did not have any direct connection with the construction industry, has lead to innovations that have benefitted stakeholders as well as users worldwide. The promise of innovation should not be viewed as a requirement to justify necessary rules to protect workers, the public and the environment. However, the fact that it often happens is something to keep in mind when industry repeats its yelling about the burden of regulation.

No comments:

Post a Comment